Products

Hybrid Equipment Series

This series of mixers are characterized by strong and efficient mixing. The two stirring shafts in the horizontal cylinder rotate in the opposite direction at the same speed. The specially arranged blades on the shaft ensure the radial, circumferential and axial movement of the materials to form a compound cycle and achieve uniform mixing in a very short time. High mixing accuracy, fast speed, low energy consumption, and sealable operation. Pneumatic, electric and manual discharging methods.

The horizontal ribbon mixer for battery materials consists of a mixing chamber body, a stirring device, a driving device, etc. The O-shaped tubular chamber is equipped with a double-layer different-direction ribbon coiled stirrer shaft. The outer spiral belt is driven by power, and its coiled form matches the rotation direction to push the material from the two ends of the O-shaped chamber to the central zone, while the inner spiral belt pushes the material from the middle to the two ends to form convection mixing. At present, the loading volume of the largest model produced by our company has exceeded 30m ³.

The rotation and revolution of the machine are completed by a set of electric field and cycloidal needle reducer. Two screws are used for asymmetrical stirring, so that the material stirring range is large, the mixing is more uniform, and the mixing speed is fast. It is more suitable for mixing materials with large specific gravity and large mixing ratio. The abrasion and compression of granular materials are small, and the mixing of heat-sensitive materials does not cause overheating danger. The preparation was stable after mixing, and no stratification and segregation occurred. Sealed and dust-free, simple operation, safe operation, convenient maintenance and long service life. All parts of the machine in contact with the material are made of stainless steel.

The model consists of four parts: transmission mechanism, horizontal cylinder, plow blade and flying blade. Under the action of plow blade, the material is turbulent along the cylinder wall in the circumferential direction. When the material flows through the flying blade, it is thrown by the flying blade rotating at high speed, thus achieving uniform mixing in a short time. The mixing time is short, and it has good adaptability to the mixing of materials with large particle size and density differences.

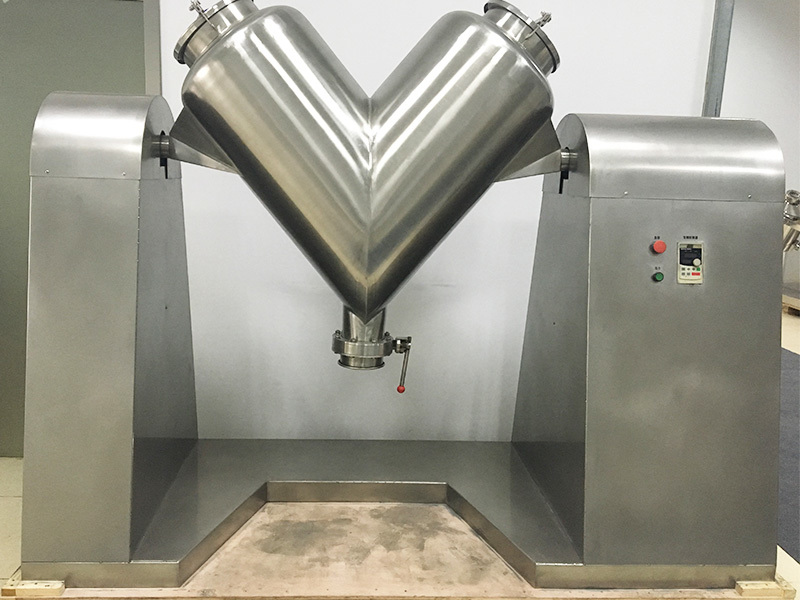

This machine is used for pharmaceutical, chemical, food and other industries more than two kinds of dry powder, granular materials mixed. The mixing barrel has unique structure, high mixing efficiency, no dead angle, the barrel is made of stainless steel material, the inner and outer walls are polished, the appearance is beautiful, the mixing is uniform, the use is wide, and it meets the GMP standard. And according to customer requirements supporting forced mixer, to fit the finer powder.

During the operation of the machine, due to the multi-directional mixing, the flow and diffusion are accelerated, and the specific gravity segregation and accumulation of materials caused by the centrifugal force of the general mixer are solved. There is no dead angle in the mixing, which can effectively ensure the high quality of the mixed materials. The machine is composed of frame, transmission system, electrical control system, multi-directional movement mechanism, mixing barrel and other components.

The two-dimensional mixer is mainly composed of three parts: rotary drum, swing frame and frame. The rotating cylinder is mounted on the swing frame, supported by four rollers and axially positioned by two blocking wheels. Among the four supporting rollers, two of the transmission wheels are driven by the rotating power system to rotate the rotating cylinder; The swing frame is driven by a set of crank pendulum mechanism, the crank pendulum mechanism is on the frame, and the swing frame is supported on the frame by the bearing assembly.

YYH series one-dimensional motion mixer is generally used in pharmaceutical, chemical, food, light industry, electronics, machinery, national defense industry and various scientific research units of powder, granular materials with high uniformity mixing. A simple and efficient powder mixer, simple structure, easy cleaning, is in line with the "GMP" powder mixing equipment.