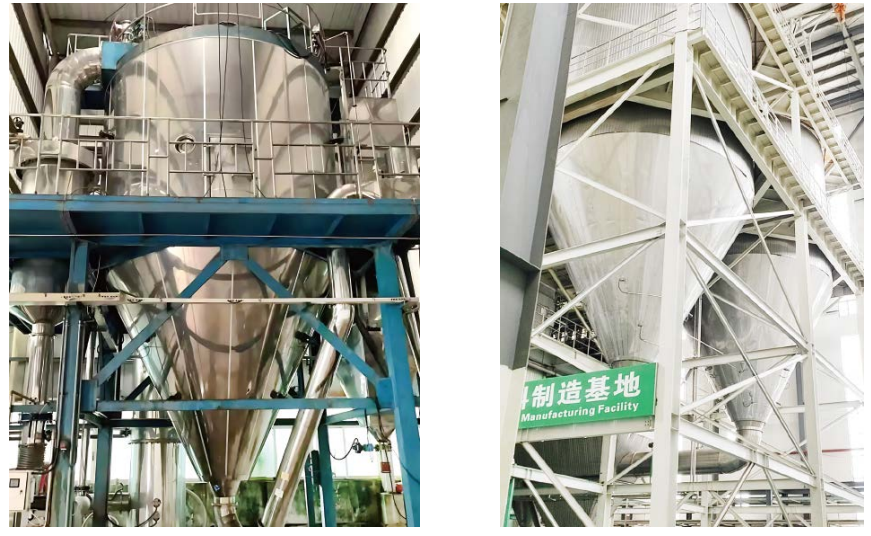

Centrifugal spray dryer

Category: Spray Dryer Series

Overview

Centrifugal spray dryers are divided into open type and closed type. They are mainly used in the drying production of battery materials, positive and negative electrode materials and sodium ion materials. They adopt high-speed centrifugal spray atomization technology (linear speed can reach 250 m/s) which is in line with the most advanced international technology. While realizing continuous drying production, they can obtain micro-spherical particles with uniform particle size, compact structure and good fluidity. To a large extent, high-speed centrifugal atomization technology, it can effectively improve or increase the packing density of the positive electrode material lithium iron phosphate, so that the monomer particles can reach 3 ~ 5μm and the moisture content of the finished product is 0.5%. The magnetic filtration technology is applied to effectively avoid the incorporation of iron ion impurities in the production process, so as to achieve the purpose of material purity and maintain the conductivity of the positive electrode material. The recycling of waste heat gas can achieve the production purpose of energy saving and emission reduction, and conform to the energy saving and emission reduction and low-carbon production mode advocated by the state.

Structural features

1. liquid supply system

1. The material liquid storage tank is provided with a stirring mechanism to prevent the material liquid from settling.

2. Before entering the atomizer, set up a magnetic filter to demagnetize to ensure product purity. 3. Choose high-speed motor direct drive atomizer. Compared with the gear drive atomizer, it has the advantages of light weight, low noise, high linear speed, wide adjustable range, no oil leakage, etc., and there is no need to support the hoisting hoist. And equipped with inverter control atomizer speed. 4. Equipped with frequency converter to control the infusion pump, the feed liquid flow is more stable, the air outlet temperature is constant, and the final moisture of the product is guaranteed.

2. drying medium

1. For the control of the electric heater, the thyristor control is designed to ensure the stability of the inlet air temperature.

2. The cold air is heated after being treated by the low-efficiency air filter, and then enters the drying room after being treated by the high-temperature air filter to ensure the cleanliness of the drying medium.

3. hot air volute

The spiral sedimentation type hot air volute, the horizontal air guide and the hot air distributor have two layers of air guide blades to rectify the hot air flow into an ideal state, fully contact with the mist droplets sprayed by the atomizer, and guide the mist droplets to descend spirally, so as not to absorb the ceiling and stick to the wall.

4. drying room

1. The drying room is made of stainless steel mirror panel, made of 304 or 316L for users to choose, with a thickness of 2~3mm, full welding and weld polishing Ra0.8, so as to ensure that the dust in the drying room does not adhere to the wall.

2. The taper angle of the drying chamber is designed to be 50 degrees to ensure the smooth discharge of the product from the drying chamber.

3. The air hammer vibration device is arranged on the outer wall of the drying chamber, and the pulse control interval is knocked to prevent dust from adhering to the wall.

5. pulse bag filter

1. The selection of filter material is made of PTFE film material, which can filter fine powder efficiently. At the same time, the film material itself is hydrophobic. When in use, it can greatly reduce the adhesion of water and other oily substances on the surface of the filter bag, and the cloth bag has good cleaning effect.

2. Due to the high exhaust temperature, generally between 100 and 130C, in order to prevent the filter bag from burning due to high temperature, the dust chamber of the pulse bag filter is equipped with a cold air outlet and temperature detection in the box. If the temperature in the box exceeds the safe temperature, the cold air outlet will be automatically opened and the heat source and other related equipment will be automatically closed.

6. air duct

In order to ensure the purity of the product, the product should contact with metal materials as little as possible during the drying process. The process should be short, the bottom of the drying tower should not be fed, and the density of the battery material is too high. In order to ensure that the materials are not classified and the product is smoothly transported to the pulse bag filter, two types of deflectors are specially set at the bend at the bottom of the drying tower, one is a conical deflector and the moon bend, and set up mixing cleaning device, so that the product will not sink in the bend.

7. control system

Touch screen operation. Programmer control, digital display temperature, pressure, atomizer and infusion pump operating frequency, according to the process requirements of automatic control of the inlet air temperature, according to the process requirements of the set air temperature automatically adjust the speed of the infusion pump to constant air temperature, to ensure the final moisture content of the product.

Previous Page

Next Page