Battery giants and Ningde era rob customers?

Release time:

2024-06-10

French start-up company Verkor said on its official website that its only goal is to speed up the production of low-carbon batteries in France to serve the European market. Since its launch in 2020, the Grenoble, France-based battery unicorn has been known for pushing Europe to reduce its reliance on Chinese suppliers.

"Batteries. Present. Future-it's in our DNA".

French start-up company Verkor said on its official website that its only goal is to speed up the production of low-carbon batteries in France to serve the European market.

Since its launch in 2020, the Grenoble, France-based battery unicorn has been known for pushing Europe to reduce its reliance on Chinese suppliers.

But so far, Verkor hasn't even built a factory.

However, this does not affect Verkor's continued access to large funds.

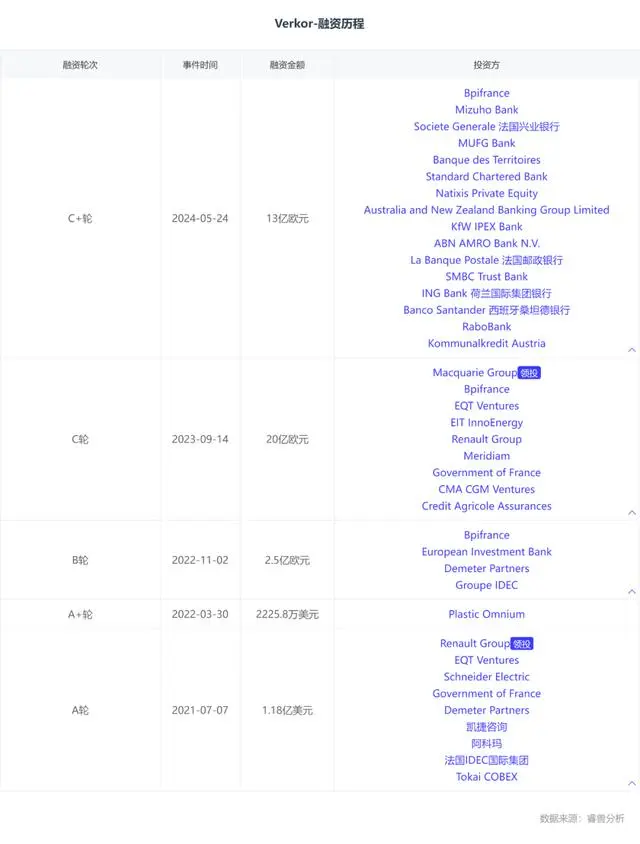

Verkor announced a 1.3 billion-euro loan about a week ago, funded by 19 banks, including Societe Generale, ING Bank, Postbank France and Santander Bank of Spain, according to Rui Beast analysis data.

With this round of 1.3 billion euros, Verkor has raised about 3.7 billion euros from investors through five rounds of financing.

Verkor's round C of 2 billion euros in September last year set a record for the largest single financing for a French start-up-Macquarie Group (Macquarie Group) led the eye-popping round of financing.

This round of financing also brings Verkor's valuation to 1 billion euros, which is seen as a key step for Verkor.

In addition, Renault is an early shareholder of Verkor and has a seat on the board of directors, and has promised to buy the "low-carbon batteries" produced by Verkor ".

New energy research organization EIT InnoEnergy, Schneider Electric, and automation giant IDEC Group are also key supporters of Verko.

Verkor co-founder and CEO Benoit Lemaignan says his company is spending € 1.5 billion to build a power battery factory in Dunkirk, France.

Verkor's rapid progress in financing is related to the growing "battery industry anxiety" in Europe.

To this end, Europe has set up two "battery alliances", ready to spend more than 7 billion euros to subsidize the development of the battery industry, in order to get rid of dependence on Chinese batteries.

The money has made a fortune for some local European battery startups, such as Northvolt, which has received more than $13 billion in equity and debt financing, and Verkor is the latest beneficiary.

Power battery has no "magic"

Bernoit Lemanen is said to have been engaged in research and development at Airbus. After almost a year of preparation, the battery company was formally established in 2020.

Fortunately, Verkor was founded in 2020, just in time for the European battery is increasingly worried about the time window.

"The car was invented in Europe, and it must be modified here." Maroš Šefčovič, Vice-President of the European Commission in charge of the Energy Union, launched a call for the development of the European battery industry in 2017.

His advice worked.

In 2017, the European Battery Alliance (European Battery Alliance,EBA) was formally established to ensure that Europe reduces its dependence on imported batteries.

In 2019, Europe launched two "battery industry alliances" to unify policies and start European local battery projects.

According to data, the subsidies provided by the two battery industry alliances reached 7.1 billion euros.

So when Bernoit Lemanen said, not without concern, that Europeans might turn their dependence on oil from the Gulf countries into a dependence on batteries from Asian countries, his Verkor became a hot potato.

He said that the battery will be the future of the car "fuel".

The CEO also promised that the establishment of a battery factory in Europe would be enough to compete with Chinese suppliers.

In his view, labor costs and management costs each account for about 5% of the final price of the battery. Although European battery manufacturers do not have an advantage in these aspects, they can also be offset by the additional transportation costs of manufacturing batteries in Asia and then shipping them to Europe.

But he did not mention the technical differences between Verkor and Chinese suppliers.

Verkor's official website is only a general description. Based on digital innovation and industrial 5.0, Verkor can generate "low-carbon batteries" that can meet the needs of the future, with both performance and environmental advantages.

In addition to Le Manion's Airbus R & D background, Verkor's COO is said to be from Tesla.

In addition, Verkor's executive team does not have a particularly obvious technical bull.

A Verkor Innovation Center (VIC) is expected to develop cells and modules.

However, considering that VIC will only start operation in 2023, it is not known how many battery black technologies it has accumulated.

From the scattered information revealed before, Verkor adopts a "follow strategy" in the technical route, rather than developing a new battery formula.

This also shows that there is no "magic" in power battery innovation ".

Benoit Lemanen said that the follow strategy can make Verkor go into operation as quickly as possible in theory, but it also indicates that it does not have a technical advantage in competition with Chinese suppliers.

"We just wanted to build a Southvolt '"

Earlier, Verkor admitted that it could not match Chinese battery suppliers.

In the face of large-scale, leading technology reserves, and the complete industrial chain of Chinese battery enterprises, Verkor once wanted to reduce the scale, in order to obtain living space.

For example, at the end of 2022, Verkor announced that it would raise 0.25 billion euros to build a Megafactory plant in advance.

This kind of factory is small in scale and does not need to spend a lot of money.

Verkor's idea is to build the battery and sell it to car customers before choosing an opportunity to expand the scale of the super factory.

But the sudden large amount of financing clearly changed Verkor's mind.

Especially after seeing the great success of Northvolt in financing, Verkor believes that he has found a development path that can be used for reference.

A Verkor executive said bluntly: "We just want to build a 'Southvolt '."

It is worth mentioning that the selling point that Northvolt has been emphasizing is that it can create "zero-carbon batteries".

Verkor, by contrast, claims to make "low-carbon batteries".

EIT InnoEnergy, one of Verkor's investors, believes that by locating the factory in Dunkirk, France, it can produce power battery products with a carbon footprint four times lower than China's.

EIT InnoEnergy is responsible for managing EBA's battery industry strategy and has been trying to recreate a battery version of "Airbus" in the field of power batteries through industrial policy ".

The level of carbon footprint mentioned by the EIT InnoEnergy may be related to the use of "green power" such as nuclear power in Verkor's super plants.

This allows it to ensure the carbon footprint of the power battery from the source.

But in the view of third-party research institutions, these are not enough to give Verkor a competitive advantage.

According to UBS's assessment, the market share of Chinese battery companies in the EU will increase to 50% by 2027.

In UBS's view, although there is a significant power battery supply gap in Europe, it will basically be filled by Chinese suppliers.

UBS believes that on the one hand, Europe has invested all its money in inexperienced local start-ups like Northvolt. On the other hand, South Korea companies that can compete with Chinese battery suppliers prefer the battery subsidies provided by the United States. Expand European production capacity.

Verkor, which is four years after its establishment in Northvolt, apparently also lacks experience in battery manufacturing.

Risk of "production and falling behind"

The latest 1.3 billion euros will ensure that Verkor will be built into a super factory.

But the company also faces many challenges, including being able to start production on time and deliver products to customers (Renault).

According to the previously announced plan, Verkor should start production of the 16GWh factory on PPT in 2023.

But things didn't happen.

Verkor's latest timetable is to start production in 2025 and expand its production capacity to 50GWh in 2030.

The problem now is: Verkor's "technology follow strategy" determined a few years ago is followed by ternary lithium batteries (NCM). At present, European and American car companies are interested in lithium iron phosphate batteries (LFP), which can reduce costs by 20%.

Tesla, Volkswagen, Ford and other car companies have increased the installation of lithium iron phosphate batteries.

Data from the Chinese market can also provide some support.

China Automotive Power Battery Industry Innovation Alliance April statistics show that lithium iron phosphate battery loading accounted for 71.9 of the total loading.

For Verkor, its NCM battery, which will be put into production in 2025, is likely to face the embarrassing situation of "production and falling behind.

Verkor also plans to explore solutions such as sodium-ion and lithium iron phosphate batteries, according to Bernoit Lemanen.

However, when lithium iron phosphate batteries are currently the exclusive technology of Chinese battery suppliers, and even South Korea suppliers cannot provide them, Verkor's supply capacity is in doubt.

And the power battery competition has now risen to the solid-state battery stage.

Battery manufacturers in China, South Korea and Japan are betting on solid-state batteries, and the common node is to launch related products around 2026 and 2027.

This puts Verkor's products, once again, at risk of being "launched and left behind.

It is also worth mentioning that in Verkor's battery park in Dunkirk, France, Huineng Technology (ProLogium Technology) from Taiwan has established a battery factory with an investment of up to 5.2 billion euros.

Huineng even received a European public subsidy of up to 1.5 billion euros.

And the product of Huineng Technology is the solid-state battery developed in cooperation with Mercedes-Benz.

For Verkor, if it has not yet laid out solid-state batteries, it is necessary to speed up the progress.

Although the cake is big enough-France alone intends to produce 2 million electric cars a year by 2030-only if Verkor can come up with enough good and enough battery products.

Note: This article is from Pioneer State. Non-Yongbang's point of view, disclaimer Yongbang this website is reprinted for the purpose of sharing. The copyright of the reprinted article belongs to the original author or the original public number. If there is any infringement, please inform us in time and we will verify and delete it. The purpose of publishing this article is to pass more industry information, for reference only, does not mean that Yongbang is responsible for its views and content. This article does not constitute any investment advice and invests accordingly at your own risk.

Previous Page

Latest News